This is a project in the “Electromagnetic Fields II” course of the ECE department at the University of Patras, for the academic year 2013 - 2014. The task was to build a motor of our choice. I chose to build a 3-pole DC motor.

The model of the motor was designed in Solidworks. This process taught me a few things about mechanical design. But most importantly, it got me to experience a day in a workshop… that place where the smallest machine can be the size of a room, and things come to life.

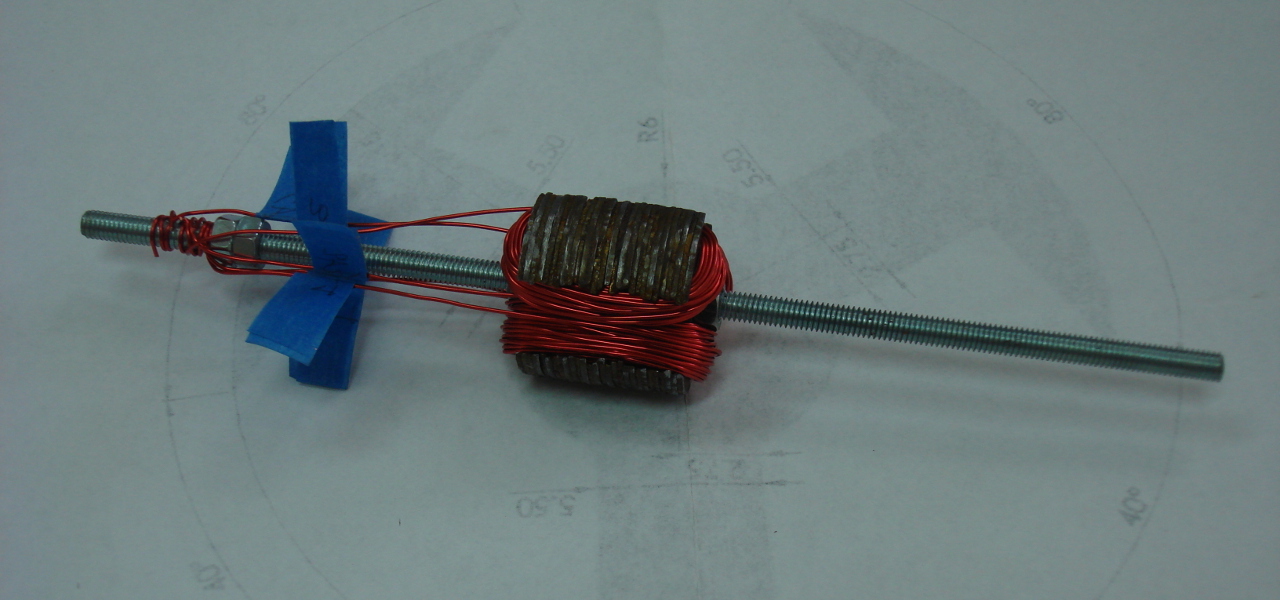

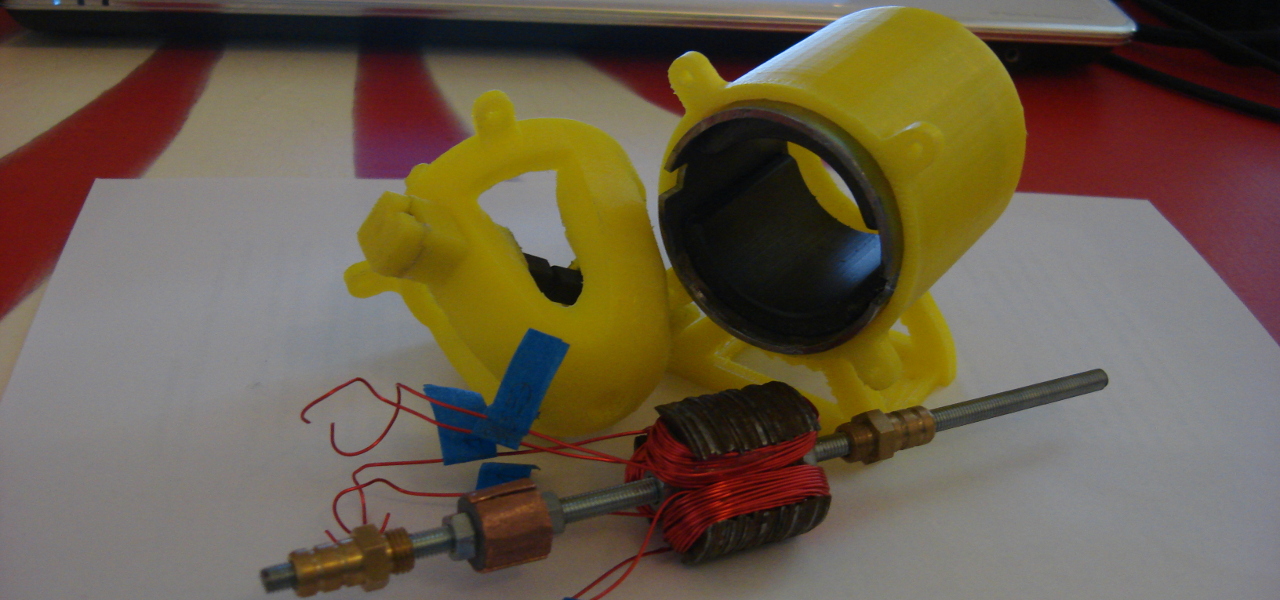

For the commutator, I used a teflon cylinder that was fitted inside a copper tube. The tube was cut and the pieces were secured on the teflon with epoxy glue. Brushes were used for the commutation.

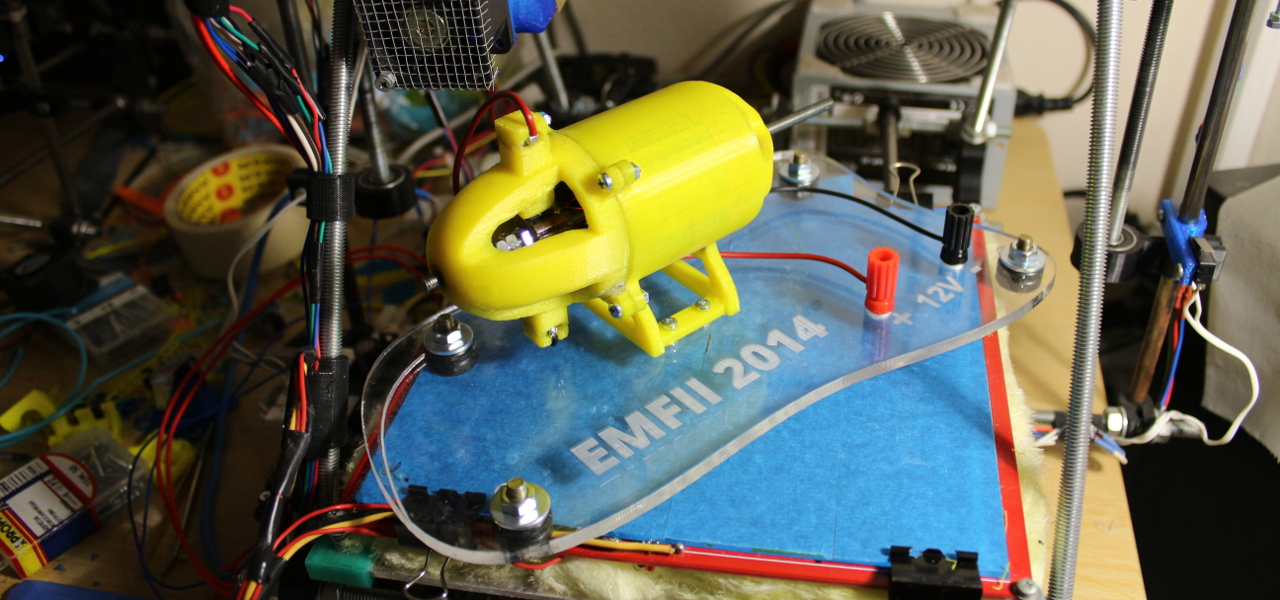

The shaft is a \(5mm\) diameter threaded rod. The core, the commutator, and the shaft itself are secured in place with nuts. The stator was 3D printed on an Ultimaker printer.

The motor is able to operate at \(30V\) with a current draw of \(1.6A\) and a speed of \(6400rpm\).

The design files are available on thingiverse.